In food processing industry, vegetable wax can be used in fruit preservatives, while in the medical industry, it can be used for making the packing of a wax-wrapped pill. It can be used for making an impregnating compound of leather, wood, and paper, polishing paste of cosmetics, furniture, and floor, crayons, wax paper, carbon paper, electrical insulation paint, leather shoes oil and lubricants for high-temperature operation precision instrument, etc. Vegetable wax is an important industrial raw material. Besides, de-waxing can improve industrial utilization value of the oil. The Significance of De-waxingĭe-waxing can increase the transparency of oil, increase its digestion rate, improve the flavor and nutritional value. The de-waxed oil can ensure clarity of oil even at lower temperatures.

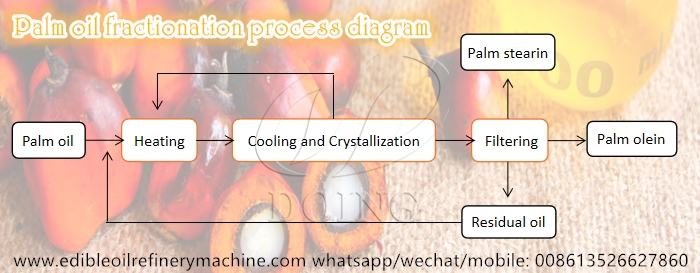

In fact, the former should be called de-waxing, and the latter is winterization. The de-waxing technology people usually refer to indicates two meaning, one is the separation of waxes which are esters of long chain fatty acids and long-chain primary alcohols, the other is the removal of all the impurities-which contain wax and saturated tri glycerides-produced during storage. Therefore, the crude oil should undergo neutralization and bleaching process before de-waxing. When filtering wax, the trace viscous material, oil-soluble pectin and soapstock compositions are attached to the wax crystals, which will often cause the jams of filter cloth, making filtering difficult. It is a necessary process for making high-quality salad oil. Oil de-waxing is separating the high melting wax and high melting solid fat by cooling and crystallization, and then removing them by filtration or centrifugal principle. What is De-waxing?ĭifferent vegetable oil and different processing methods result in different wax content. As edible oil calls for high level and strict quality standard, oil producers are keeping a watchful eye on its de-waxing process. If the oil turns cloudy when consumers store them at low temperatures, they may mistakenly think the oil is spoiled, and the bad smell when cooking may bring the producer into trouble. At the same time, the existence of wax will degrade the smell, flavor, and palatability of the oil, and also reduce the digestion and absorption rate, decreasing the oil quality and nutritional value. Under the temperature of 30 centigrade, the solubility of the wax in the oil will decrease and the wax will precipitate and forms crystals, with the extension of time, these crystalline grains will gather and amplify, the vegetable oil turns cloudy, reducing the transparency and causing a certain effect on the color. In the process of making oil, the wax will enter into the oil. In the skin, shell and cell walls of vegetable oilseeds, such as corn germ oil, sunflower oil, and rice bran oil, there is a certain amount of wax.

0 kommentar(er)

0 kommentar(er)